Maximize efficiency with our

Ball Segment Valves

Our Techno-G valve meets unique process requirements

Go to the video

About Techno-G

YOUR PARTNER FOR SOLIDS HANDLING

We guarantee a reliable product, brought to you by a dedicated team that assists from the initial query to installation and providing continual support throughout your Ball Segment Valve’s lifecycle.

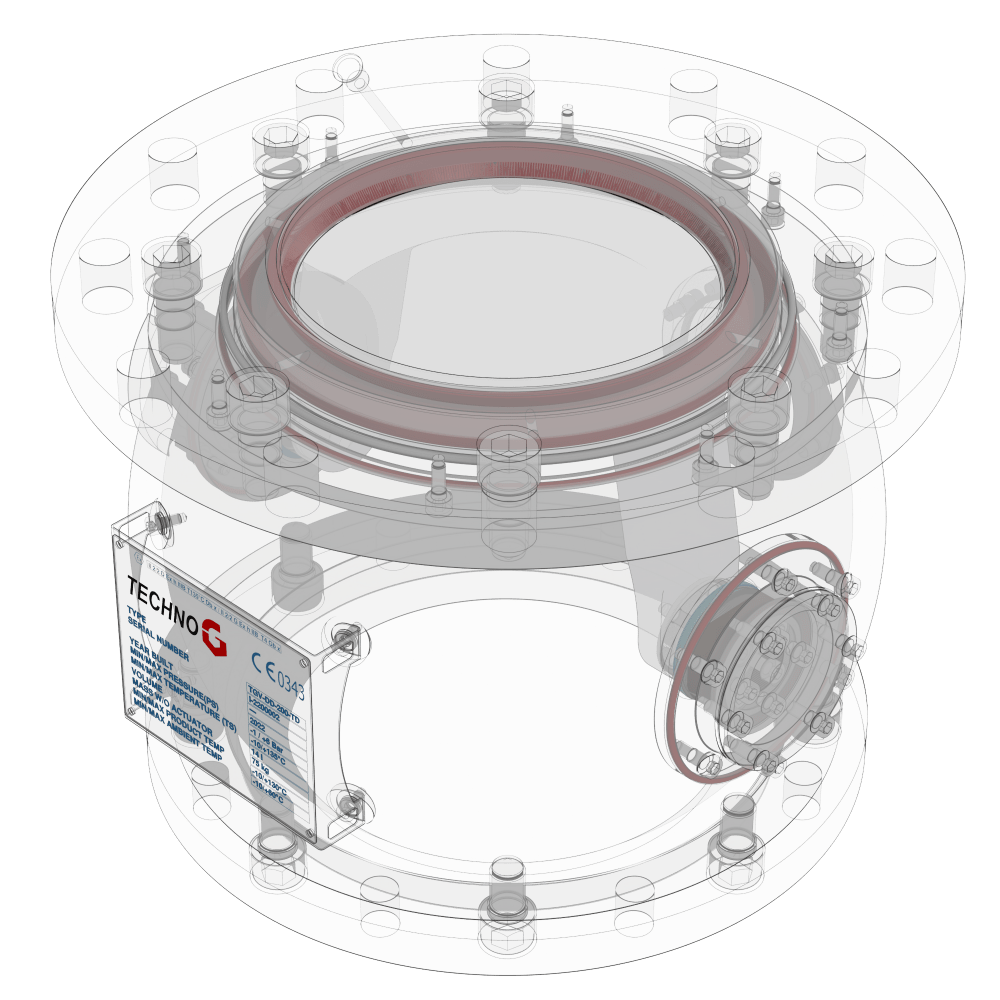

Techno-G’s Ball Segment Valve is renowned for its exceptional quality and precise engineering. Designed with an inflatable seal, this valve ensures a reliable and tight closure, effectively managing pressure differentials. With its robust construction, the Ball Segment Valve is purpose-built to handle solid materials, making it an ideal choice for high-end applications where reliable and efficient solids handling is paramount.

SEGMENTED PRECISION, SEAMLESS PERFORMANCE

Techno-G, a redeveloped, modular range of Ball Segment Valves

Techno-G Segmented Ball Valves, are developed as state-of-the-art engineering combined with modular component design, based upon experience which goes 30 years back to the very beginning of the Segment valve concept.

WHAT WE DO

A Selection Of Industries We Serve

Discover the breadth of industries we proudly serve, where our expertise and solutions have made a significant impact.

The principle of the

Inflatable seal

High demands in terms of vacuum and pressure tightness are easy to achieve by retro-fitting our innovative sealing system in existing ball segment valves. The special geometry of the inflatable seal enables long-term, reliable sealing against a wide range of solids. There is a wide range of seal materials available. For your typical process, Techno-G’s inflatable seal is available in the following materials:

- EPDM White

- EPDM Black

- Viton White

- Viton Black

- Perlast FFKM

SPECIFY A TECHNO-G VALVE FOR YOUR APPLICATION

Key features of the Ball Segment Valve

Explore the key features of the Ball Segment Valve, engineered for optimal performance, including its full bore design, unobstructed product discharge, and exceptional pressure tight seal.

The Ball Segment Valve, renowned for its excellent reliability, ensures a long operating life, meeting diverse process demands with its precision-engineered, vacuum-tight seal.

The Ball Segment Valve, with its sanitary design, ensures no dead areas, promoting hygiene and efficiency in various applications, from vacuum drying to pressurized process reactors.

The Ball Segment Valve is cGMP-conform and CIP-able, ensuring it meets stringent pharmaceutical standards and can be easily cleaned in place, enhancing process efficiency and safety.

The Ball Segment Valve’s full bore design ensures unobstructed product discharge, optimizing flow and preventing blockages for efficient and reliable operation.

he special geometry of the inflatable seal enables long-term, reliable sealing against a wide range of solids. There is a wide range of seal materials available.

Working principle

Inflatable seal

The inflatable seal expands upon pressurization, ensuring a tight fit and enabling secure vessel transitions.

DEFLATING

OPENING

CLOSING

INFLATING

TESTIMONIALS

Hear From The Experts

Our industry experts share their insights on the Techno-G Ball Segment Valve series.

In addition, I directed our engineering team to revamp the existing ball segment valve lineup, evolving it into a modular range that can be produced in-house. Leveraging the collective expertise of Techno-G within our corporate network, we've designed the new Techno-G Ball Segment Valve series. We are thrilled to unveil this new range at the Powtechshow in Germany.

I am confident that this new offering will meet market expectations and benefit from the solid reputation established by the earlier Techno-G units already in operation.

As a result, the new Techno-G- G Ball Segment Valve consists of fewer parts and is therefore less complex to build.

This ensures a competitive cost price, but above all a high quality in product sealing, choice of material, and construction size.

PROCESS APPLICATIONS

Tailored to perfection

Techno-G products are versatile, serving a multitude of applications such as vacuum dryers, paddle dryers, vacuum locks, blenders, centrifuges, conical dryers, mixer vessels, and reactors. They provide not only optimal functionality but also dependable and secure operation.

Techno-G products are versatile, serving a multitude of applications such as vacuum dryers, paddle dryers, vacuum locks, blenders, centrifuges, conical dryers, mixer vessels, and reactors. They provide not only optimal functionality but also dependable and secure operation.

Techno-G valves are utilized across a wide spectrum of sectors, from Pharmaceuticals, Chemicals, and Fine Chemicals to API, Food, Cosmetics, Minerals, and Metals, among others. Whether it’s ensuring consistent flow control in pharmaceutical production, exact modulation in the creation of fine chemicals, or sterile management in food processing, our Ball Segment Valves consistently offer unmatched efficacy tailored to your industry’s unique needs.

OUR BLOG

News & Press about the Techno-G Ball Segment Valve

Techno-G & De Dietrich at POWTECH, Nuremberg – Booth 9-527

Techno-G2025-09-22T15:09:37+00:00Save the Date: The international process engineering community will meet again in Nuremberg from 23–25 September 2025!Techno-G is joining forces with De Dietrich Process Systems at POWTECH in Nuremberg, booth 9-527. Together we are presenting the latest solutions in solids handling, including the innovative ball segment valve with inflatable seal...

Techno-G Introduces Advanced PTFE-Protected Ball Segment Valves for Chemical Processing

Techno-G2025-03-19T16:06:08+00:00Techno-G has announced an enhanced line of Ball Segment Valves featuring PTFE protection technology specifically engineered for solid handling in chemical and pharmaceutical applications. The valves deliver exceptional non-stick properties with surface energy below 20 mN/m, temperature resistance up to 220°C, and complete chemical resistance across the pH 0-14 range. These...

Contact Us

Company address

- Company address

- Techno-G

- James Wattstraat 8

- 8912 AS Leeuwarden

- The Netherlands

- A Jongia company

- Techno-G is a proud part of Jongia Mixing Technology, combining over 80 years of experience in providing innovative solutions for var