Techno-G & De Dietrich at POWTECH, Nuremberg – Booth 9-527

Techno-G2025-09-22T15:09:37+00:00Save the Date: The international process engineering community will meet again in Nuremberg from 23–25 September 2025!

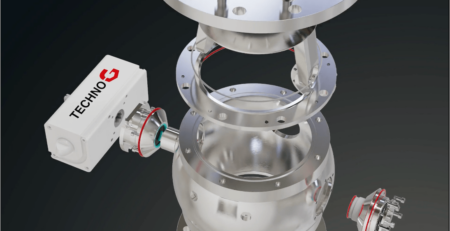

Techno-G is joining forces with De Dietrich Process Systems at POWTECH in Nuremberg, booth 9-527. Together we are presenting the latest solutions in solids handling, including the innovative ball segment valve with inflatable seal – designed for hygienic, safe and efficient operation.

De Dietrich will showcase its expertise in complete process systems for the chemical, pharmaceutical, food and green chemistry industries. From solids handling to filtration, drying and turnkey process solutions, our teams will be available to share insights and discuss how we can support your process needs.

We look forward to welcoming you at POWTECH and exploring how we can shape efficient and sustainable process solutions together.

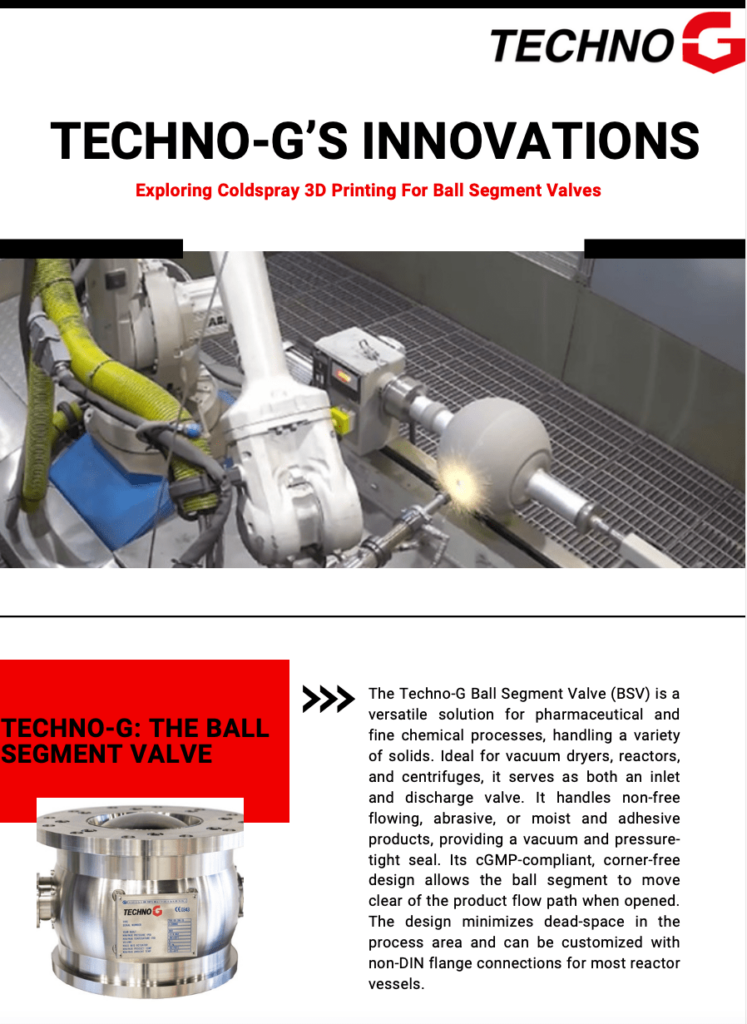

Download our free whitepaper

"Exploring Coldspray 3D Printing For Ball Segment Valves"

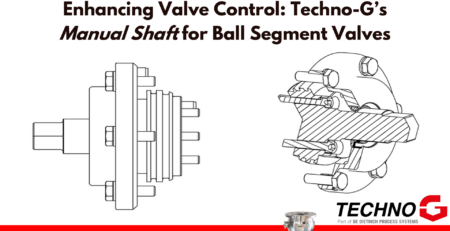

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. It handles non-free flowing, abrasive, or moist and adhesive products, providing a vacuum and pressure- tight seal. Its cGMP-compliant, corner-free design allows the ball segment to move clear of the product flow path when opened. The design minimizes dead-space in the process area and can be customized with non-DIN flange connections for most reactor vessels.

The Techno-G Ball Segment Valve (BSV) is a versatile solution for pharmaceutical and fine chemical processes, handling a variety of solids. Ideal for vacuum dryers, reactors, and centrifuges, it serves as both an inlet and discharge valve. Learn more.

PTFE Coating Properties:

- Surface Energy: <20 mN/m

- Maximum Service Temperature: 220°C continuous operation

- Chemical Resistance: pH 0-14, resistant to most acids, bases, and organic solvents

- Coefficient of Friction: 0.05-0.10 (static)

- Coating Thickness: 15-25 μm standard application (customizable)